- New melt shop will add 5 million metric tons per year at Vijayanagar, Toranagallu site

- Will produce high-quality carbon steels

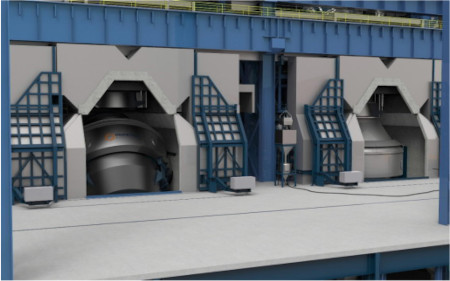

- Order includes BOF(LD)-converters, ladle furnaces and slab casters

- Gas cleaning and dedusting systems ensure high environmental standards

Indian steelmaker JSW Vijayanagar Metallics Limited, a wholly owned subsidiary of JSW Steel Ltd (JSW Steel), has placed an order with Primetals Technologies to supply equipment for its new Steel Melt Shop No. 4 in Vijayanagar, Toranagallu. The order includes two BOF(LD)-converters, two ladle furnaces, gas cleaning and dedusting systems, two slab casters as well as level 1 and level 2 automation systems. The new melt shop has a design capacity of 5 million metric tons per year and will mainly produce high-quality carbon steel. It is part of a major project of JSW Steel to expand its JSW Steel Vijayanagar Works facility’s production capacity. Primetals Technologies will be responsible for engineering, supply of equipment, and advisory services for erection and commissioning.

The two 350-ton-BOF(LD)-converters feature the maintenance free Vaicon Lamella suspension system, water cone and barrel air cooling and will be equipped with slag stoppers, including the thermographic automatic slag identification system SlagMon, quick exchange type oxygen blowing lances and the Lomas converter off-gas analyzing system. A dry type gas cleaning system will reduce dust content to 10 mg/Nm³ at the stack. A steam type heat recovery system will improve energy efficiency, the secondary dedusting system will provide low work zone and roof top emissions. The two 350-ton-ladle furnaces will be equipped with copper-plated electrode arms and the Melt Expert electrode control systems.

The two two-strand continuous slab casters are designed to produce slabs in a width range of 900 to 1,650 millimeters at thicknesses of 220 and 260 millimeters. The metallurgical length amounts to 34.5 meters. A wide variety of steel grades can be processed, including the complete range of ultra-low to high carbon steels, deep drawing, structural, peritectic and HSLA grades, micro and low alloy steels, strip grades and high silicon electrical steels.

The casters are fully equipped with advanced technology packages, including LevCon mold level control, DynaFlex mold oscillation, Mold Expert breakout prevention and DynaPhase phase transformation modelling for maximum possible slab quality. Latest design DynaGap Soft Reduction 3D in all segments, Dynacs 3D cooling model, and Quality Expert for on-line slab quality assessment are also provided. The melt shop and the casters are also equipped with features to make them ready for Industry 4.0.