LaVa-X and RAYLASE: technology partnership for increased productivity and reduced resource consumption with laser welding in vacuum.

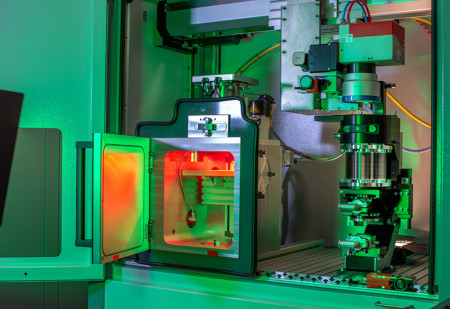

Fuel cells are considered a key technology in the energy transition. Due to the expanding electromobility, the demand for bipolar plates for fuel cells is also increasing. It is therefore increasingly important to weld the plates quickly and with as little effort as possible. The highest quality requirements must be met at all times. For optimized welding processes, LaVa-X, a solution provider for laser beam welding in a vacuum, is cooperating with RAYLASE, a provider of components for rapid deflection and modulation of laser beams.

Bipolar plates perform important functions within the fuel cell. In addition to quality requirements, high demands are also placed on the cost-effectiveness of the components – in this case especially on the welding process. Laser beam welding in a vacuum (LaVa wielding) is ideal here, as it delivers high productivity with optimum quality while using little energy. Leveraging conventional single-mode fiber lasers, humping effects occur from a welding speed of approx. 700 mm/s. The quality of the weld becomes insufficient due to this effect. Compared to conventional laser welding, LaVa welding enables high welding depths and high-quality weld seams with less energy consumption.

Bundled technology experience around the laser

RAYLASE develops and manufactures high-precision opto-mechanical components, control cards and software for the rapid deflection and modulation of laser beams that can be easily integrated into machines and systems. The laser deflection units are used, for example, in the welding of automobiles and batteries as well as in the production of packaging, electronic components, solar panels, industrial textiles and clothing.

“Especially when welding bipolar plates for fuel cell production, larger processing areas are often required. LaVa-X works with our AXIALSCAN FIBER-30”, says Bernhard Dauner, sales representative at RAYLASE.

“I personally really appreciate working with the deflection units”, says Dr. Christian Otten, CEO of LaVa-X. “Instead of rotating the component, it is much easier to guide the laser beam accordingly. This allows us to process several components at the same time.” The SUPERSCAN IV-15 from RAYLASE which is located outside the vacuum chamber is used for this purpose. “We can use it to set particularly high oscillation frequencies and high amplitudes and thus use wobble welding effectively. The high changeover dynamics of the small mirrors are very important to us as well when the laser power is low. We also use the 20 and 30 versions of the SUPERSCAN IV, but only for powers above 2 KW or if we need a smaller spot with a long focal length at the same time.”

The model-based digital control of the SUPERSCAN IV offers high dynamics and terminal velocity. These have a particularly positive effect in MOTF (marking and processing on the fly) applications in connection with a RAYLASE linear translator module. The robust, water-cooled master block design – in conjunction with the optional air purge – enables laser powers of up to 6 kW.

Together, LaVa-X and RAYLASE increase the productivity of laser welding in a vacuum many times over, thereby also reducing resource consumption.