For the expansion of its steel plant in Danapur, Indian steel producer BMM Ispat awarded Danieli Corus a contract for a complete, 0.88-Mtpy blast furnace complex. The plant will be installed in an iron ore-rich area in India’s Karnataka state, where BMM Ispat currently produces pellets, sponge iron and a variety of long products.

The blast furnace will have a 680-m³ working volume for a design capacity of 2400-2600 daily tons of hot metal.

It will feature Danieli top-charging unit with a compact DANCU distributor developed to minimize operating costs thanks to maximum availability and minimum maintenance, and dry gas cleaning technology to eliminate the requirement for large quantities of scrubbing water, while retaining maximum residual thermal energy in the top gas.

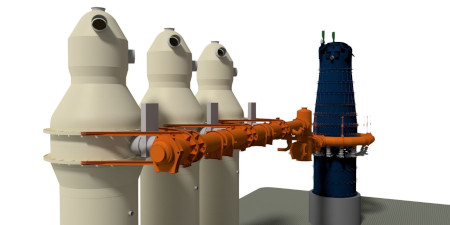

The hot blast stoves will be based on dome combustion process, with a refractory design proven for ultra-long campaign life capability based on free expansion allowance and a shell mechanical design, resulting in low stresses to prevent premature fatigue and inter–crystalline stress corrosion cracking.

The furnace will operate on a charge mix of 80% pellets and 20% lump ore, while the pulverized coal-injection system will inject up to 250 kg/tHM.

A third-generation, Danieli Corus level-2 automation system will support operators in maximizing process efficiency and stability. Browser-based for maximum user–friendliness and customizability, it will enable system access from any device within the plant network.