- Project included modernization of existing electric arc furnace

- Primetals Technologies supplied a new twin ladle furnace and new material handling system

- Overall plant capacity to increase substantially

- Comprehensive plant optimization thanks to a high degree of automation and the use of robotic systems

- Robotic systems to further improve occupational safety

Primetals Technologies has received the final acceptance certificate (FAC) from Gerdau Special Steel North America for the modernization of its electric steel plant in Monroe, Michigan, U.S.A. The project included modernizing the existing electric arc furnace (EAF). The electric steel plant was also equipped with a new twin ladle furnace, a new material handling system, and related auxiliary equipment.

Increased productivity

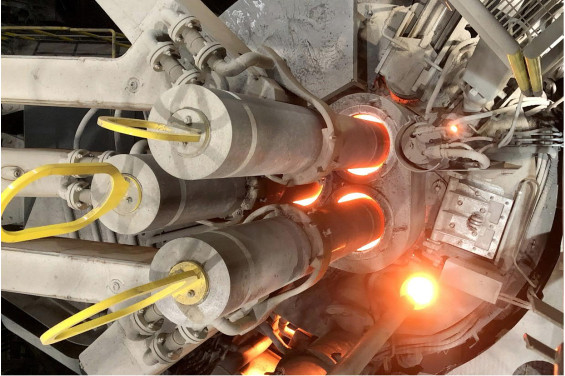

This upgrade has increased the plant’s overall annual production capacity of special rolled end products. End-to-end automation and the use of LiquiRob robot systems increase productivity and reliability, optimize workflows in the steelworks, and reduce operating costs. The robotic systems also improve worker safety by performing potentially dangerous tasks, such as taking temperatures and samples.

A complete package

Gerdau Special Steel North America is a leading manufacturer of special steel bars, which are mainly used in the automotive industry. Gerdau selected Primetals Technologies based on the overall technical solution proposed. The company also appreciated that Primetals Technologies would provide the complete package — mechanical equipment, electrical and automation equipment, and a high-power EAF revamp solution. Additionally, Primetals Technologies provided a compact and technologically advanced solution for the twin ladle furnace and integrated the new material handling system in accordance with the requirements of the existing plant.

Improved safety measures

This project was part of an investment package to modernize the plant and increase employee health and safety. Primetals Technologies was responsible for engineering and supplying the process equipment for the EAF, the 110-metric-ton twin ladle furnace, the material handling system, auxiliary equipment, and the structural steel work. The company also supervised the construction and commissioning of all installations. The scope of delivery encompassed the associated electrical installations and automation, the power supply — including transformers, the complete end-to-end process automation, and three LiquiRob systems. Solutions such as automatic sand refilling, a weighing system, and the automated tap hole manipulator are now optimizing EAF operation and increasing worker safety.